Published on Sep 16, 2023

The objective: For the last 2500 years, the concept of elevators has completely evolved in mechanics, while still maintaining the key core concept of a lift. Magnetic levitation is just a simple idea that was derived years ago. Maglev technology has been applied to trains. I tested the technology of magnetic levitation to move an elevator.I predicted that if the number and strength of magnets is increased, then the height of levitation of the elevator will increase. I discovered that there is a direct relationship between the strength of the magnet and the height of levitation.

The concept of a conventional elevator relies heavily on gears, motors, high-tension cables, and electromagnets. The purpose is to coordinate all components to either raise or lower the elevator that is attached to it. The gears act as screws, do not move but only rotates on their axis. The motors either power of alternating and/or direct current, which propel the gears to function either in a negative or positive direction. The tension cables pull the elevator up or down.

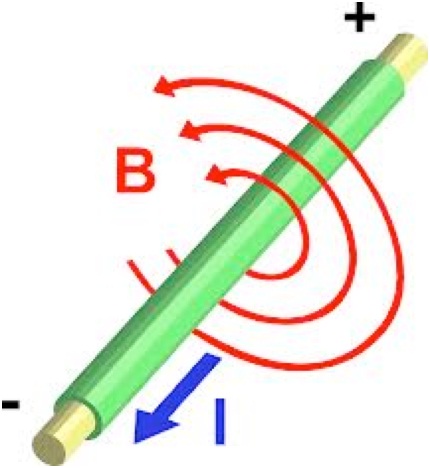

Electromagnetism is the production of a magnetic field created through the electric current in a wire-round coil and strengthened by a soft iron core. If the coil is wrapped around a magnet, the structure is called a solenoid. The current from a source directly correlates to the magnitude of the magnetic field. The electromagnetism concept works in a way of monitoring strength, as the current can be changed to match any specific value, in order to indirectly increase the field that it produces. The number of coil and the space between the coils work in altering the magnetic pole attraction patterns.

The first beginnings of magnetic levitation go back to John Mitchell in 1750, where he noticed two magnets repelling when the same pole of each magnet was put together. In 1922, Hermann Kemper in Germany pioneered attractive-mode (EMS) Maglev and received a patent for magnetic levitation of trains in 1934. Soon, Maglev development in the U.S. began as a result of the High-Speed Ground Transportation (HSGT) Act of 1965. In the US, in 1966, James Powell and Gordon Danby proposed the first practical system for magnetically levitated transport, by using superconducting magnets located on moving vehicles to influence currents in normal aluminum loops on a guideway. The moving vehicles were automatically levitated and stabilized, both vertically and laterally, as they moved along the guideway. The vehicles were magnetically propelled along the guideway by a small AC current. In 2000, the Committee of the Ministry of Transport of Japan concluded "MagLev has the practicability for ultra high speed mass transportation system." In 2006, Chinese developers unveiled the world’s first full-permanent magnetic levitation (Maglev) wind power generator at the Wind Power Asia Exhibition 2006 held June 28 in Beijing.

The basic difference between a mechanical elevator and a MagLev elevator is that it is based on electromagnetic suspension. There is one system of axial and circular coils attached to the elevator in a magnetic field which counteracts the effect of gravity, suspending the elevator. The principle of the motion is that there will be electromagnet coils on the undercarriage of the elevator and also on the outer frame. These coils attract or repel culminating in motion.The elevator also has buffer zones at the bottom and the top which have a very high perpetual repelling magnetic field thus ensuring the safety of the elevator.

Maglev elevators are a much better way to move people around buildings than by normal elevators. It is cheaper, faster, safer, quieter, and has a much longer service life. There is less friction due to no contact between the pulley and the suspension rope. Therefore higher speeds can be attained, which is useful in tall skyscrapers. Maglev guideways will last for much longer time with minimal maintenance because there is no mechanical contact and wear. Maglev technology is very energy efficient and it consumes electricity. When they consume electricity, no carbon dioxide is emitted. Also the power required for the elevator would be reduced with the assistance of magnetic levitation. Also the safety system using electric buffers will be a failsafe. Such a design would be better suited to electrical 21st century than a mechanical elevator.There are some disadvantages with Maglev elevators. Guide paths are bound to be more costly than conventional guideways used by regular elevators but their cheaper maintenance over time will pay for itself.

The problem I want to address is that normal elevators require continuous inputs of large amounts of energy and have high maintenance costs.

I attempt to solve this problem by using the technology of magnetic levitation to move an elevator.

This would be more energy efficient and cheaper to use and maintain.

If I change the strength of magnets in order to levitate an elevator, what will happen to the height of the elevator?

• 5 Wood Blocks, 5/8” x 1 3/8” x 6”

• 2 Large High Force Magnet Strips, 1/2” x 23 1/2”

• 2 Small High Force Magnet Strips, 1/2” x 5 7/8”

• 2 Large Simple Magnets, 1 3/4” x 1”

• 10 Simple Latch Magnets, 3/4” x 1”

• 4 Plastic Angles

• 30ml Contact Cement

• 1 Wooden Base

• 1 Compass

• 1 Silicone Tube

• 1 Ruler

• 1 Hand Saw

• 1 Utility Knife

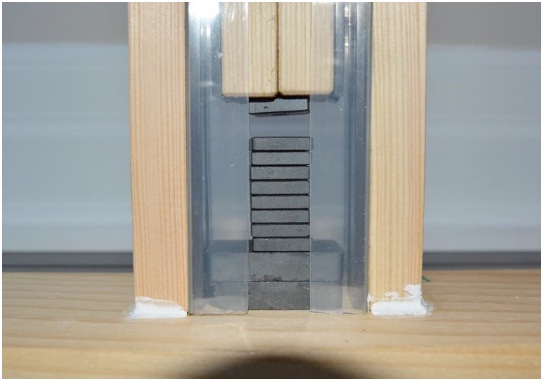

1. Two wooden blocks were attached to each other on ends with contact cement to make one side of the elevator track.

2. Step #1 was repeated with two other wooden blocks to make the other side of the elevator track.

3. The four plastic angles were attached to the sides of the elevator tracks, 5/8” away from each other.

4. The hand saw was then used to cut the last wooden block in half and made into an elevator shaft.

5. The two large and the two small magnetic strips were cut in half with the utility knife.

6. The compass was used to find the north and south poles of the magnetic strips.

7. The four large magnetic strips, with the south pole down, were then applied to the plastic angles, on both tracks, with contact cement, 5/8” away from each other.

8. The four smaller magnet strips were attached to each side of the elevator with the south side down, 5/8” away from each other.

9. The elevator tracks were then attached vertically with contact cement, to the wooden base close enough so that the elevator could levitate.

10. Silicone was placed on each of the tracks for stability.

11. One small latch magnet was attached magnet to the bottom of the elevator with the south side down.

12. One large magnet was attached to the base of he elevator track with the south side down.

13. The elevator was then levitated in between the tracks.

14. The height of the elevator from the base magnet was then measured.

15. Step #14 was then repeated using different sizes and number of the magnets.

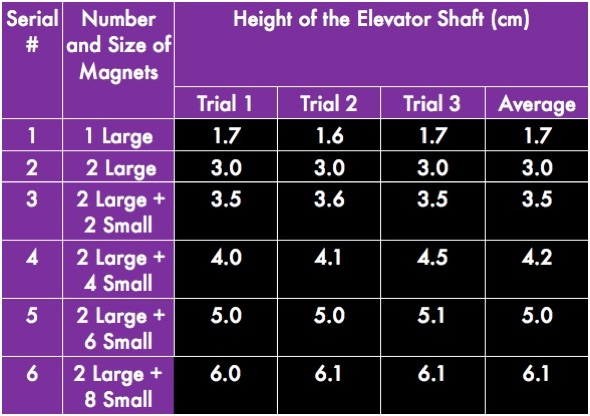

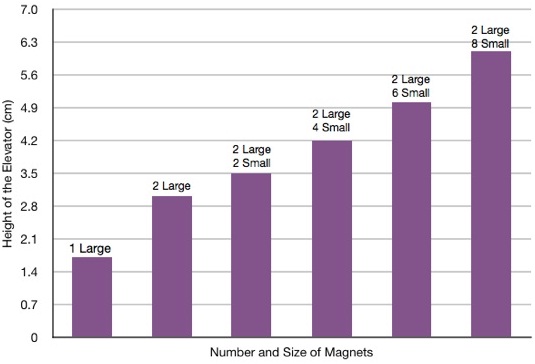

In conclusion, when I changed the number of magnets at the base of the track, the levitation of the elevator shaft changed.

I discovered that as I increased the number of magnets, the height of levitation increased, showing a direct relationship between the two variables.

For example, with one base magnet, the levitation height was 1.7 cm. With two large and eight small magnets, the levitation height reached to 6.0 cm.

Therefore, the data supports my prediction, and I accept my hypothesis.

I think this happened because when the number of magnets increased, the force of repulsion between the opposite poles of the elevator magnet and the base magnet increased. This lead to the higher height of levitation.

The elevator was more difficult to levitate than the train because of the addition of force of gravity on the elevator shaft. I overcame this by adding a much larger magnet at the base of the track and a small magnet at the bottom of the elevator.

I also tried to add another magnet on the top of the elevator shaft and tried to pull it with a similar assembly on top. This was attempted to make the elevator move up and down using the force of attraction. This however was not possible as the force of attraction was not as easy to measure. The force of repulsion could be quantified by a scale but the force of attraction cannot.

• http://www.askanexpert.com/

• http://www.virtualsciencefair.com/

• http://wordnetweb.princeton.edu/perl/webwn?s=ping-pong+ball

• Parker, Lewis. Simple Machines. United States of America: Perfection Learning®, 2006.

• Williams, John. Machines. England: Wayland (Publishers) Ltd, 1991.